The ultimate electric turbo.

2.749,00 €

First: understand what it does

Improve your car’s Power Band

Thanks to the aditional air flow and increased intake pressure, peak Hp and peak torque will lower in RPM. Meaning you will get a much faster accelerating car.

Yes, you will increase your horse power

Dependent on the displacement and RPM range of the car, the increased air flow and pressure will result in more horsepower with the TORQAMP.

And what is more important, get more torque!

Thanks to the instant increased air flow, your engine will produce much sooner the increased and maximum torque, resulting in a much faster and more powerful accelerating car.

Performance

- Instant pressure built up

- Torque increase of 35% or more

- Increases engine power up to 44%

- Eliminates turbo lag when used in combination with a turbo

- Universal aftermarket device with the largest torque increase and the quickest responsiveness

Installation

Plug & Play and standalone

Usable on any engine and any engine size

No radical or irreversible changes. Keep your car original!

- Easy and quick to install and uninstall

- No plumbing and no intercooler needed

- Can be mounted in any position

- Very compact

- Fits on any engine in any engine bay

- Can be easily installed on your next car or project as well

- Easy control and integration with any kind of vehicles Engine management and control systems!

For installing the TORQAMP no dramatic changes are needed. Actually the car can remain in its original condition. For naturally aspirated engines, The TORQAMP can be placed directly on the intake manifold before the throttle body.

In case of a MAF Sensor the TORQAMP can also be placed directly on the intake manifold or an intake tube that is directly connected to the intake manifold. Though, it is important that the MAF sensor is placed on the suction side of the TORQAMP.

On turbocharged engines the TORQAMP can blow directly into the turbo, or can be placed behind it on a parallel tube or even behind the intercooler on a parallel tube. We do suggest to use a bypass valve (which can be found in our website) since the mass flow on larger turbo charged engines can be relatively high.

Control options

Manual or gas pedal

- Simple ON/OFF lever switch placed under gas pedal (Standard in the kit)

- Control the TORQAMP speed based on Throttle Valve Position 0-5V signal*

- PWM signal from an output of your ECU*

- Combining with a Turbo? Control the TORQAMP speed based on the throttle valve position and intake manifold pressure*

What's in the kit

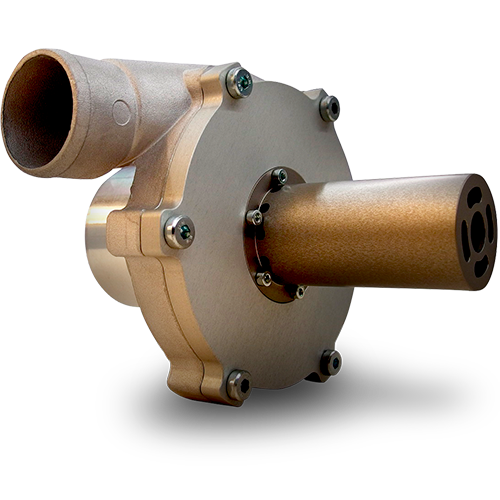

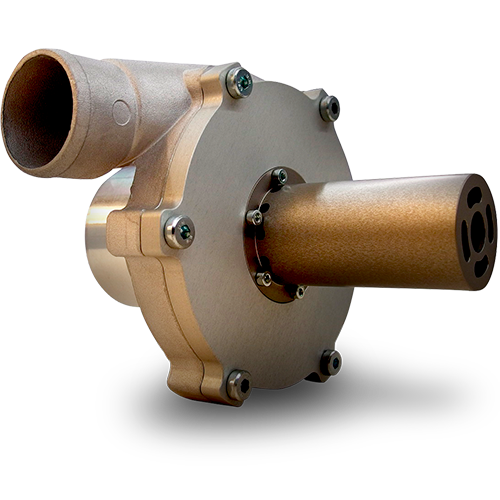

Electric turbo

The one and only turbo powered with a 5Kw electric motor

Power box

8Ah of electric power in only 7.2 Kg

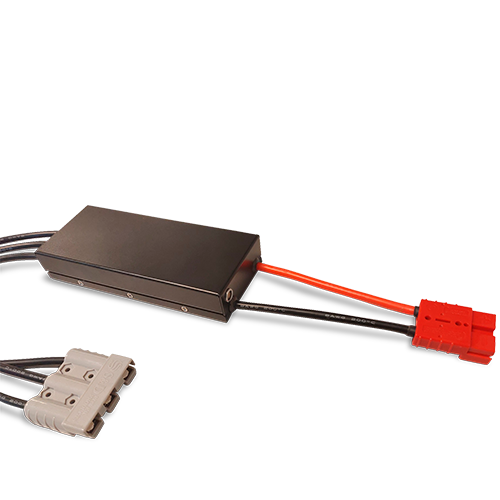

Motor controler

Flexible motorspeed controller to control your boost

Lever switch

Can be mounted below the gas pedal for instant boost and get a nice “kick-down” feeling

Design at its best

Profesional design

4 years of development resulted in a durable design which is based on the best materials. Each component of the TORQAMP is calculated extensively, is simulated in simulation software and produced in several prototypes. Each prototype was exposed to destructive testing, tests in extreme conditions and endurance tests.

Durable design

Not only are all the parts of the TORQAMP designed to be more robust then theoretically necessary, but the TORQAMP compressor is also designed in such a way that most parts can be disassembled and re-assembled. This with the idea for our customers to purchase a product for life and not just for the lifetime of their current vehicle.

High quality materials

Only the best materials available are selected for the TORQAMP. The semi-ceramic bearings are a nice example. These are pre-lubed with special high speed grease.

Different materials were researched for each application and extensively tested both in laboratory conditions, test rigs as in vehicles.

Also the electronics of the TORQAMP are selected on the application. Every chip or resistor is selected based on their usage in the automotive sector, but also based on the conditions in which they are used, such as exposure to heat and vibrations.

Let's talk numbers

Pressure Ratio

The air flow that is pumped in to an engine by the TORQAMP, is plotted as massflow against pressure.

The Mass flow is shown in grams of air per second and pounds of air per minute, and is plotted against the pressure ratio that the TORQAMP is able to generate.

Air Temperature

As a result of the compression the temperature of the air in the engine’s air-intake is increased with maximum 35-40 degrees.

The temperature increase of the air as a result of the compression ratio is plotted against the Mass flow in grams per second/ pounds per minute. This means that when air is compressed the air temperature will increase as a result of the compression. In this graph can be seen that temperature of the air decreases as the mass flow increases as the compression ratio lowers.

It's made for you

For Beginners & expert tuners

For any vehicle

For any engine

It's made for you

For Beginners & expert tuners

The TORQAMP is so easy to install, basically anyone can do it. But the TORQAMP can also be used to built complex high tech high power performance motor-sports applications.

For any vehicle

Classic cars, modern cars, race cars, kit cars, your daily, 4X4’s, pick-up trucks, as long as it has a combustion engine.

For any engine

Even for power generators, tractors, trucks, boats, powersport vehicles, planes, the TORQAMP can change a heavy load into a small hump.

Technical specs

The turbo compressor

- Weight: 2.4 kg

- Dimensions: 180 x 190 x 155mm

- TORQAMP intake diameter: 76 mm

- TORQAMP outtake diameter: 52 mm

- Max over pressurer: 0.4 Bar / 5.8 Psi

The power box

- Weight: 7.2 kg

- Dimensions: 235 x 115 x 185 mm

- Nr. of cables: 4

- Cable weight: 0.6-1kg

- Battery technology: Lithium Polymer

- Internal charger: 500w

- Battery capacity: 8Ah